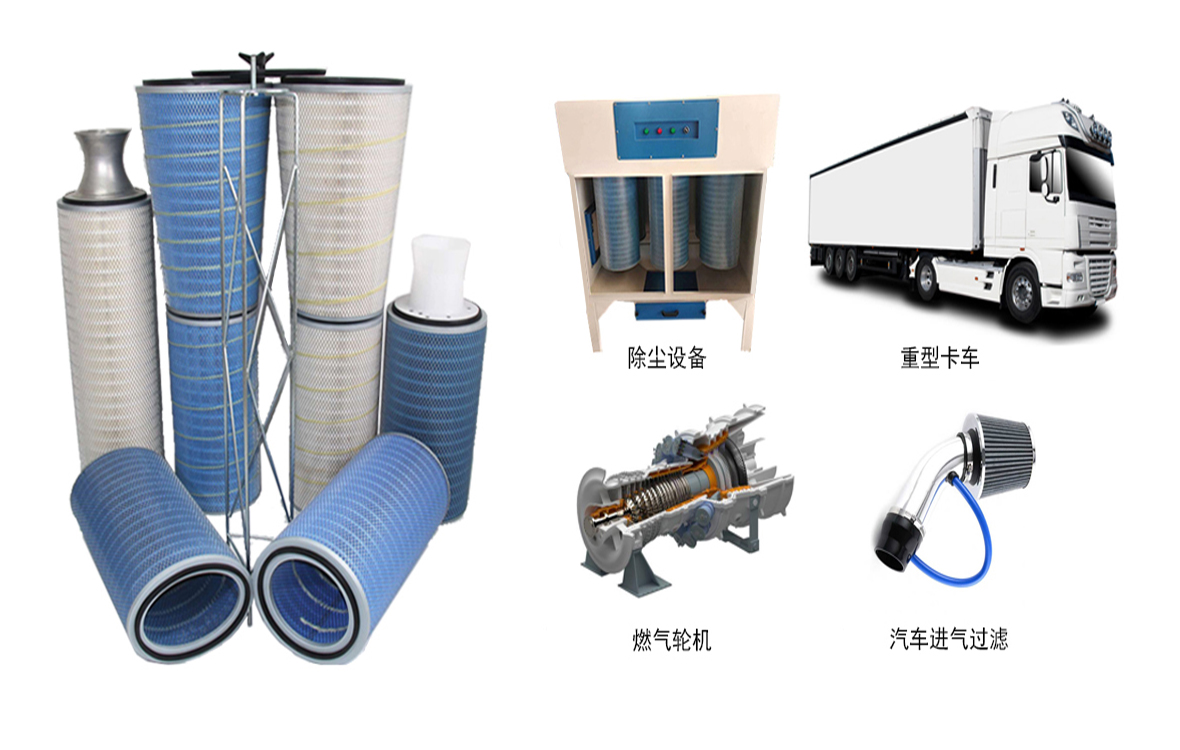

Nanofiber and wood pulp paper combined with high strength, small pore size, can achieve high efficiency and lower pressure drop, easy back blowing dust removal, widely used in commercial vehicle intake system, gas turbine, air compressor , industrial dust removal, heavy duty truck filter and other fields.

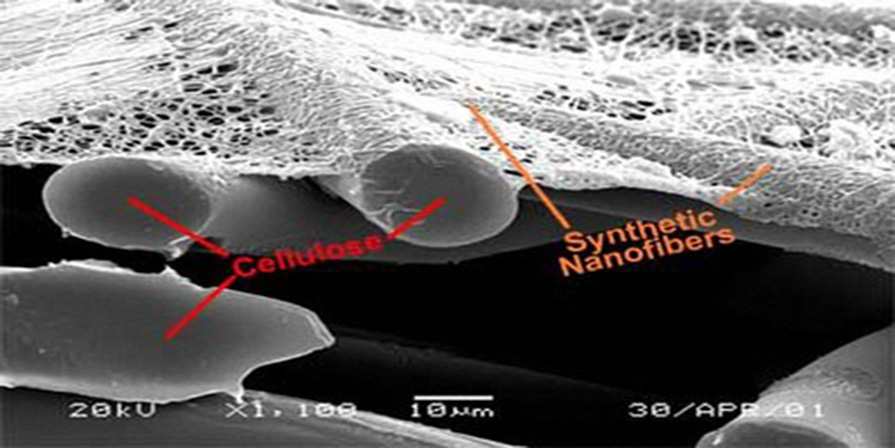

Wood pulp fibers, which can provide bulk, strength, and permeability, are the dominant fiber material in filter paper. Among the fiber properties, fiber diameter is a key factor affecting the filtration properties of filter paper, as revealed by various filtration theories . Reducing fiber diameter is the dominant way of increasing filtration efficiency. Theoretical predictions and investigations indicate that, when the fiber diameter is less than 1 μm, the filtration efficiency of filter paper can be dramatically improved by the slip-flow effect and the huge specific surface area of ultra-fine fibers. Nanofibers provided significant increases in filtration efficiency with a relatively small reduction in permeability.

Especially suitable for air intake filters for internal combustion engines and gas turbines. Conventional air filters quickly become obstructed with dirt, reducing vital engine air intake, leading to poor engine performance and low fuel efficiency. They require frequent replacement.Wood pulp paper with a synthetic nanofiber layer - are better constructed than conventional filters, remove more contaminants from the air, and also provide less airflow restriction. Not only do they have a higher filtration efficiency, but they also have a larger dirt holding capacity.

1、Selection of high quality filter paper substrate

2、Electrospinning Nanotechnology

3、High efficiency, low resistance, high energy saving, easy back blowing

4、Flame retardant treatment