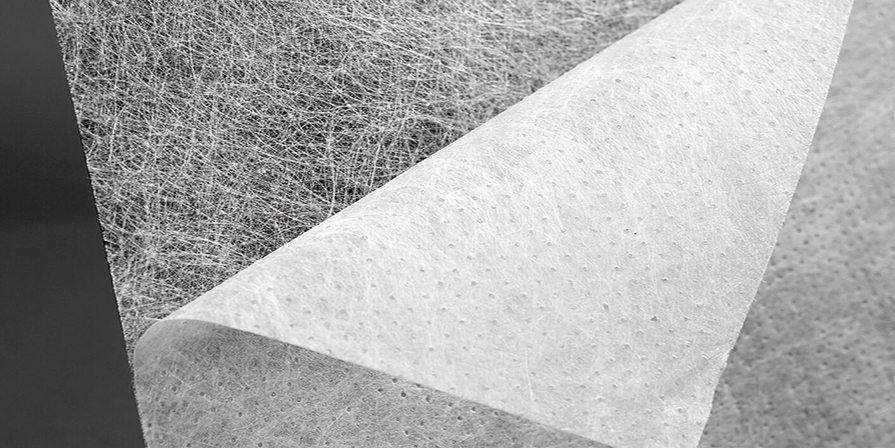

The nanofiber medium-efficiency panel filter media developed by Foshan Membrane Technology Co.,Ltd. meets the antistatic test standards of ISO16890 and EN779, which reflects the characteristics of high efficiency and lower pressure drop of nanofiber media, and has better filtration performance stability. It combines hot-air cotton and electrostatic cotton or meltblown media can achieve a suitable level of efficiency and dust holding capacity, and have lower pressure drop and lower energy consumption than glassfiber materials. Especially suitable for high-end application industries such as biology, pharmacy, medical treatment, semiconductor and so on.

Electrospinning technology is used to compound the antibacterial nanofibers on the nonwoven fabric. Due to the fine diameter, high porosity and large specific surface area of the nanofibers, the antibacterial effect is longer and the efficiency is higher. It can be compounded with activated carbon, meltblown and electrostatic cotton, and has multiple functions. Good adsorption, higher strength, easy forming, lower pressure drop, longer service life, good adsorption and filtration effect on TVOC and microbial pollution. Widely used in air conditioning filtration system, air purifier, vehicle filtration and other fields.

1) Broad spectrum antiviral and bacteriostatic

2) The speed of antiviral and bacteriostatic is fast

3) The antiviral and bacteriostatic efficiency is high